Reducing the remedial rate – a retailer guide

December 17, 2021

With the skills gap in the KBB industry continuing to widen, and installers difficult to come by at the best of times, getting your design, order and installation right first time is more crucial than ever, so you don’t have to face costly remedial work.

Damian Walters

According to the BIKBBI’s Damian Walters, the UK KBB market is facing a number of significant problems right now. “We’ve got this perfect storm at the moment. One of the biggest problems we’re seeing is a delay in materials or parts getting to the retailer. This, combined with fewer installers to do the work, and demand greatly outstripping supply, means that jobs can potentially be delayed for months.

“Where remedials are concerned it’s the responsibility of the retailer to fix these problems, whether they can find an installer or not. When you throw The Consumer Rights Act into the mix, where you may have to pay to fix problems and offer compensation, what started out as a simple-seeming fix, might end up costing the retailer thousands.”

Other reasons for going back to a job might include correcting a design flaw or fixing something faulty. In some cases, such as with supply issues, it’s out of the retailer’s hands. Whatever the case, you’ll want to avoid remedials, and particularly right now.

However, there are ways to mitigate against remedials, lessen the remedial rate, or hopefully avoid them altogether.

Get the design right first time

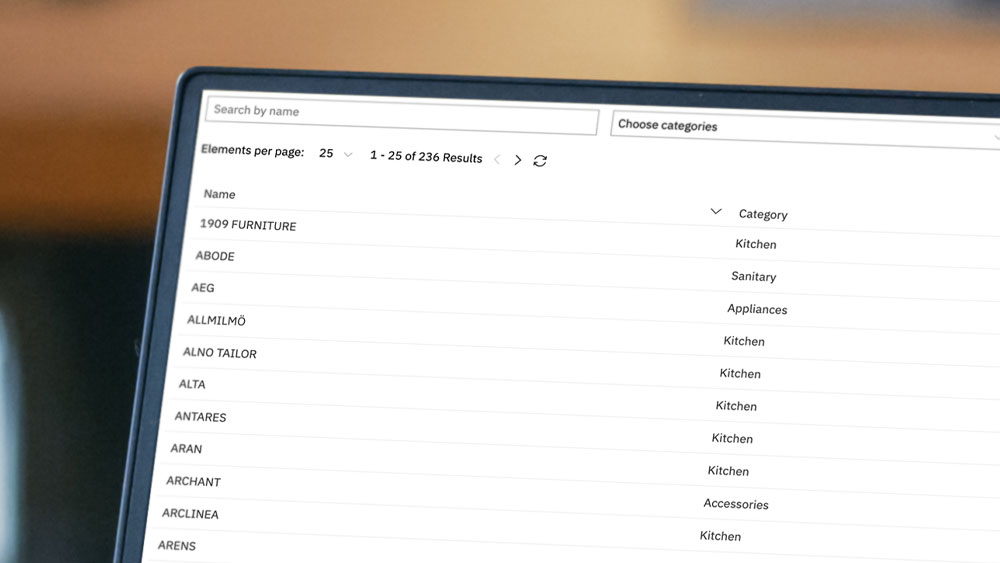

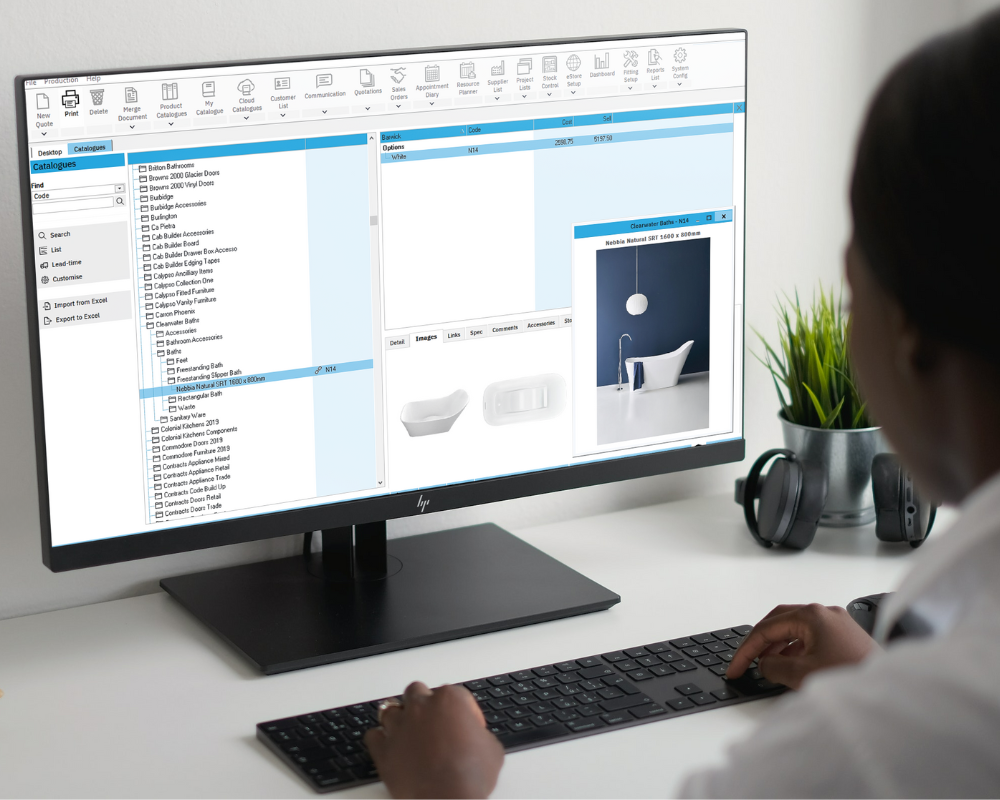

It pays to be as meticulous as possible in this first stage, check and double check and check again. Of course, using a software package that you can rely on for accuracy, with manufacturer catalogues that you know are regularly updated will help here.

Tristan Wedgbury

Compusoft training team manager, Tristan Wedgbury, comments: “We often see retailers and designers having the same issues and regularly forgetting to add smaller items to quotes. When they forget the items, they then just decide to add them in for free rather than giving the customer another quote. But while something like a cutlery tray may only cost £20, over years these little expenses add up to thousands of pounds.

“With certain catalogues available on Winner Flex, you’ll be given a list of codes relating to add-on products when you’re creating the design, which will prompt the designer to either offer these add-ons to the customer, or add them on to the quote so that they don’t forget.

“In addition is the Sales Assistant feature which shows all the accessories you could have. Plus, a lot of the processes are automated and certain items, including worktops, are added automatically, and can’t be forgotten. All of these tools reduce mistakes in the first place and help get it right first time.”

Make sure everything is ordered correctly

With Winner Flex, order lists are done automatically as you design, but it’s worth going over this to double check that you have ordered everything you need. Lead times have increased from a maximum of two weeks up to four weeks or even a couple of months. So, something as small as a few missing end panels could put the job back significantly if forgotten.

Ashley Chapman

Ashley Chapman, designer for Pieve Interiors comments “Being able to see the floor plan, elevation view and 3D drawing all at once is really useful when designing as it allows you to see the design from all angles at any given time. Winner prompts you for appliance codes etc. when initially planning a unit, so this helps to avoid missing key details and prices further down the line.”

Ensure EVERY part is in stock

An up-to-date manufacturer catalogue should help here, but again, it’s worth double-checking that everything ordered will arrive together, and on time. It’s worth maintaining a close relationship with your suppliers and their reps so you can be sure you’re kept in the loop if any items are not likely to be available.

Make sure the design is viable with an installation survey by a reputable fitter

“Installers don’t really care that much about aesthetics,” Walters comments, “they want to be sure that the kitchen will be functional and work as intended, so an installation survey is crucial for the fitter to determine that the design will work.”

Having that reassurance from an installer that everything has been planned correctly and into its right place should also offer peace of mind for everyone involved.

Ashley Chapman adds, “Clear communication is key. The fitter should always check measure on site prior to fitting. This gives time to flag any issues, order extra material and make any changes prior to the start date.”

Ensure the installer has everything he needs to carry out the installation correctly.

Because of the shortage of qualified installers, the ones that are out there working can pick and choose what jobs they want to do. And they’re likely to pick the highest paying projects that are least hassle. So, it’s in your interest as a retailer to make the job as straightforward as possible.

The first thing is to make sure you have all the furniture and parts and that nothing is missing. Secondly, an installer pack which includes a parts list and all schematics/measurements is critical for ensuring the job is done correctly.

Finally, ensure there are no surprises for the installer by clearly marking installation plans with everything the installer might need to be aware of, and remember that clear, concise and consistent communication is key.

On this point Ashley Chapman explains her approach, “I print out my own fitting instructions inclusive of floor plans with element list, elevation drawings and worktop plans. It has all the measurements required along with showing colours of the units, customers address and contact numbers. I always add comments to each unit to highlight any issues or to detail the connected load required on appliances.”

It’s a good idea to mark your plans with electrical or plumbing elements that can’t be moved so the installer knows exactly what he will find on site. Doing this will also clearly demonstrate that the plan will work practically as well as just on paper, as it will prove that you’ve considered all the practicalities.

Where the installation plans are concerned, Wedgbury also suggests adding in comments or codes so that the plans are as detailed as possible, leaving no room for error. “Sit down with your installer or installation team and come up with terms that everyone is happy with and understands. Then you can save these terms in a database on Winner Flex and use them time and time again. Consistency in communication really is crucial.”